Our third success story takes place in a factory that manufactures medical devices, from raw material to finished products through transparent manufacturing.

Moving all operation lines on one facility from paper to digital. The approach was bottom-up: From raw material via sub-assemblies to finished medical device. This approach led to an acceleration in delivery of 26 workflows.

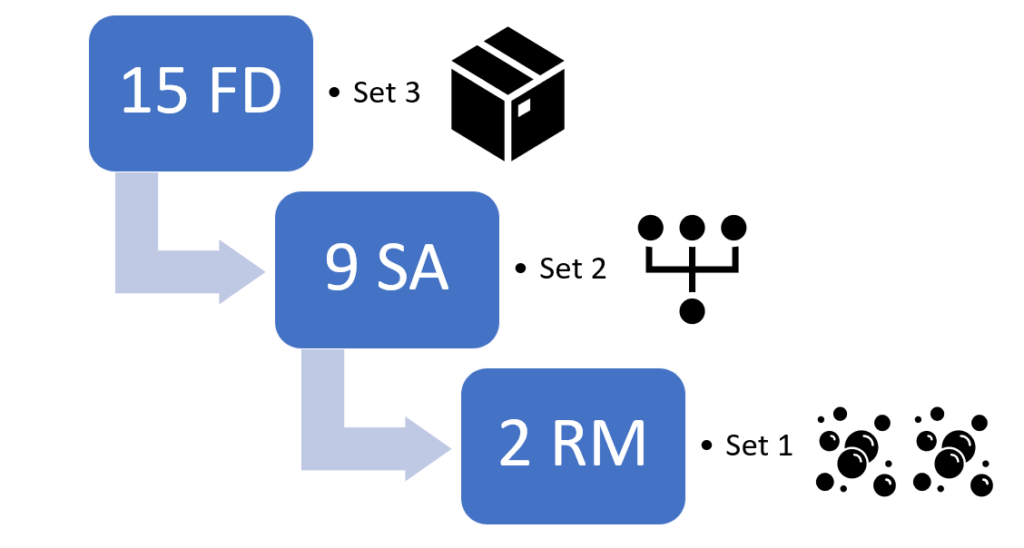

The first workflow took 3 months, solving miscommunications between site and global project team. The second workflow was added in 1 month. A bunch of 9 workflows was added in 3 months after that and finally we could do 15 workflows in 3 months, parallel to dry-run testing of the set of 9 and UAT of the earlier set of 2. The routine was based on truth discipline: testing with example data from ERP through the interface! Elimination of assumptions and fake test data.

The example data and the explanation of the hierarchy in the data made the on-site stakeholders understand the system the way it was meant for in phase 1. As a key to success, understanding of the system had been achieved, followed by the participation so that the team can work in a disciplined manner towards the same goal!

For our routine during the process, we have used the truth discipline with which our company operates. In this case this involved testing with examples from the ERP through the interface.

references: upon request.