Discovering hidden value in data

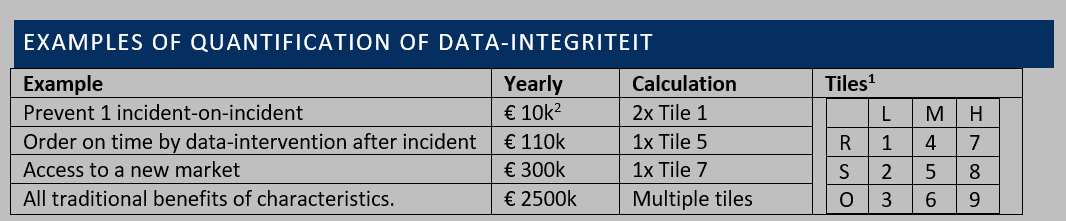

In industrial automation, there are many companies that ignore potential value. This can be quantified in money when it includes risks and efficiency, although for some value this is less relevant. Think about safety, health, reputation, a good culture, etc. This value is hidden in all the data that is produced by these companies. By collecting data-characteristics, Empiriqation is able to visualize this hidden value. That allows a substantial improvement of the daily work experience.

Example 1 – replacing a needle

It is often small things that make industrial processes stop. In this example it was obviously a misplaced bottle in a robot with a less obviously placed injection needle. After correction of the bottle the robot didn’t work anymore. It took two weeks of searching and communication and finally traveling to the site before the bend needle was found. Replacement took less than 5 minutes. By clear agreements about usage of a camera at this location, the robot can be inspected remotely by an expert upon request. This results in shorter incidents, less delays, better experience and more trust.

Example 2 – beyond incident solution

One interface at a big production facility handled a big amount of data simultaneously from system A to B. In this case a network outage overnight was solved the next day. Result: a barrack full with pallets not marked with A or B quality. The truckdriver couldn’t load the right ones for transportation. Finding out the right pallets one-by-one by hand would take weeks – such a delay wasn’t agreed with the customer. What now?

Because the supporting party for the interface had knowledge of the data-model of system A and system B, a correct report could be delivered within 10 minutes, showing which pallet had A or B quality. This way the transportation was only delayed for a half day.

Sometimes abstract is complex and translation is needed

Empiriqation uses an layer of abstraction to make data-characteristics apprehensible. This makes the underlaying data-model well-known so that go some steps beyond traditional incident resolution. Also, it allows to predict upcoming incidents or detect incidents immediately so that resolution is delivered before a delay occurred. Also, chances for improvement can be found which aren’t noted directly during the daily activities. Also, the modern OT/IT security requirements are included in the characteristics of data integrity.

Limited offer: One week analysis for free!

To the first 3 responders, a week of analysis is offered free of charge. During such analysis, a top 5 is made of data characteristics. This can also be quantified so estimate the return-on-investment of implementing monitoring and alarming.

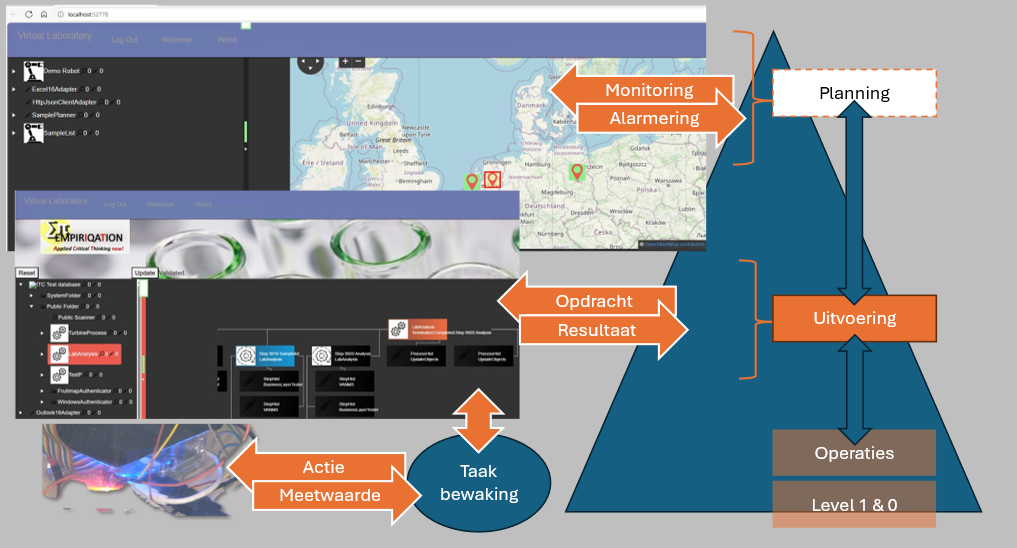

Solutions for laboratories and industrial automation

Based on a short analysis, the possibilities can be investigated that are already on the site, to do the monitoring and alarming. Platforms that are fit for this purpose are reporting platforms or service-busses because they allow to query the data-characteristics and share them safely. For example Soffico, BizTalk, Microsoft AIS and Power BI.

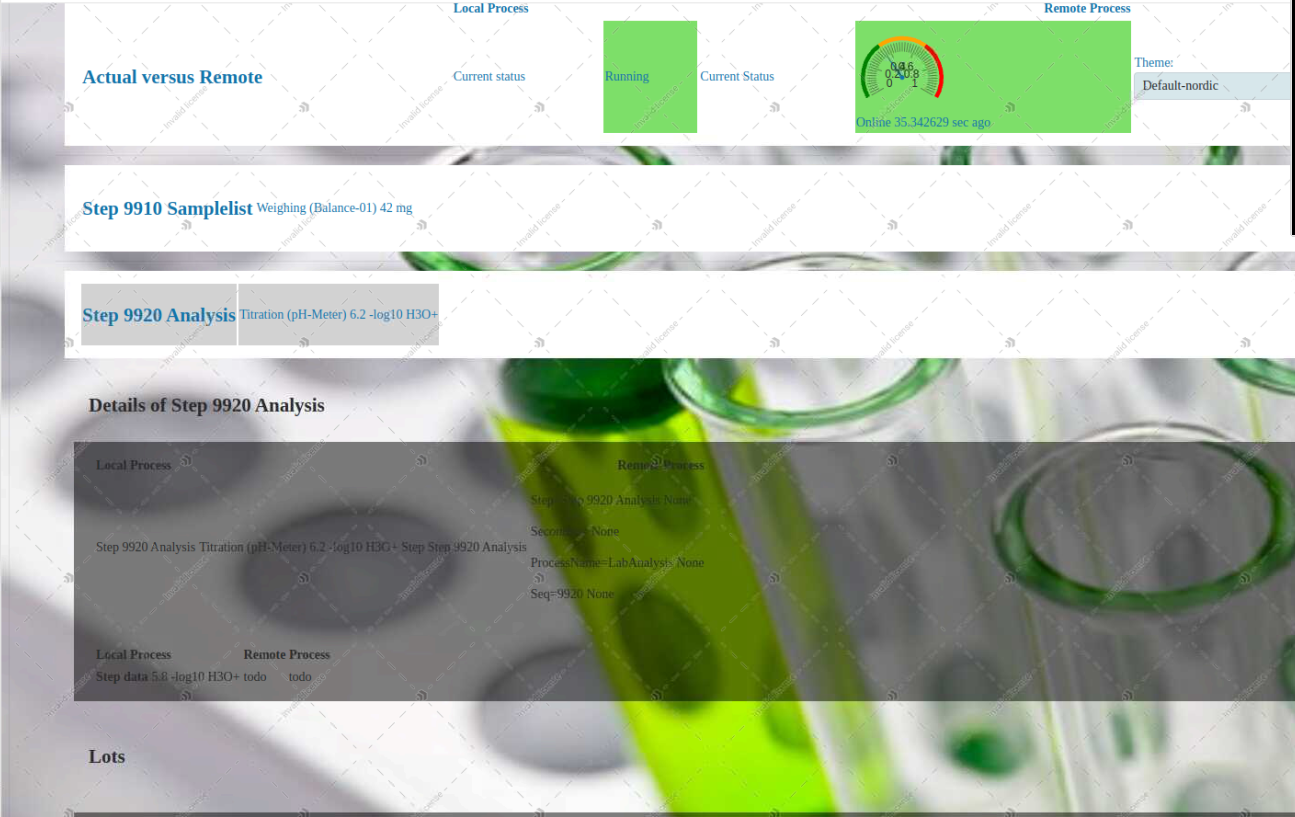

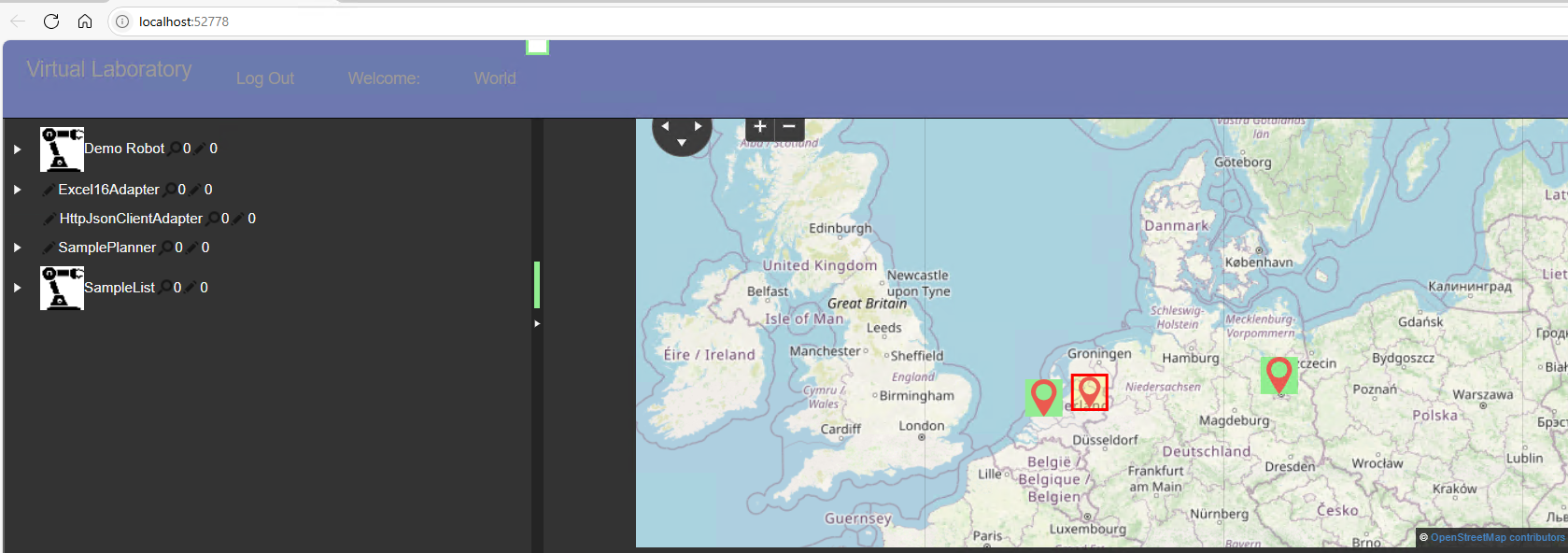

Our step-up demo solution

Our demo solution can serve as monitoring/alarm system as well as an data-interface and control module over small tasks. Such as lab-analysis execution. Its security model allows for a secret corridor between OT and IT network for dedicated tasks.

A live demo/sandbox situation is available (sometimes this sandbox is down for sporadic maintenance).